|

|

|

|

|

|

|

|

|

| |

|

|

| |

M I M |

|

|

|

|

|

| |

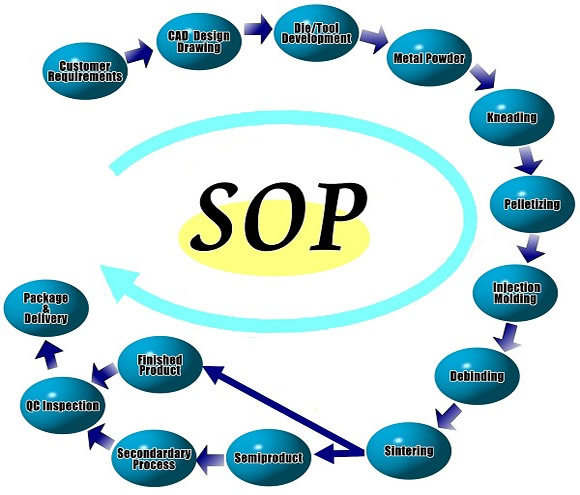

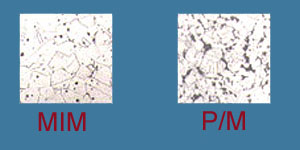

Metal injection molding (MIM) is a technology that combines the strengths of conventional powder metallurgy and plastic injection molding. It is the most cost-effective process in making small parts with complicated shapes. The debound and sintered parts could gain more than 95% density of conventional metal working parts.MIM Technology is suitable for small mechanical parts that require high complexity, high precision, high mechanical property and high productivity.

| Comparison of propertise between MIM and other processes |

| Character |

Machining |

P/M |

Invesatment

Casting |

MIM |

| Density |

100% |

< 95% |

100% |

> 95% |

| Mechanical Properties |

good |

fair |

fair |

good |

| Accuracy |

high |

high |

fair |

fair |

| Complexity |

high |

low |

fair |

high |

| Surface Roughness |

fine |

coarse |

fair |

fine |

| Plating Quality |

good |

poor |

good |

good |

| Productivity |

low |

high |

fair |

high |

| Production Cost |

high |

low |

fair |

fair |

| MIM

Process Advantage & Characteristic |

※ Cost Down |

| ※ A Variety of shape and design |

| ※ High Precision Control |

| ※ Applicable on various mixture of Alloy and special Metal |

| ※ Applicable on product with high complexity and high Precision |

| ※ High density and Strength |

| ※ Flexible Design |

| ※ Good surface finish for Polishing |

| Comparison of shaping capabilities between MIM and investment casting |

| Properties |

MIM |

Invesatment Casting |

| Min. Wall Thickness |

0.4 mm |

2 mm |

| Max. Wall Thickness |

10 mm |

Unlimited |

| Min. Bore Diameter |

0.4 mm |

2 mm |

| Tolerance at 14 mm Diameter |

+/- 0.06 mm |

+/- 0.2 mm |

| Surface Roughness Ra |

1 um |

5 um |

| Typical material composition and properties |

| Properties |

Fe-8% Ni |

Fe-50 Ni |

Fe-50 Co |

4650 * |

316L |

440C |

| g/cm3 |

7.6 |

7.7 |

7.7 |

7.5 |

> 7.6 |

> 7.5 |

Tensile Strength

( MPa ) |

450 |

455 |

205 |

1500 |

500 |

1600 |

Elongation

( % ) |

25 |

30 |

< 1.0 |

2 |

40 |

2 |

| Hardness |

Rb80 |

Rb50 |

Rb80 |

Max.HRc 55 |

HRb 70 |

Max.HRc 55 |

| C |

< 0.15 |

< 0.05 |

< 0.05 |

0.5 |

0.03 |

1 |

| Ni |

8 |

50 |

|

2 |

11 |

0.6 |

| Mo |

|

|

|

0.5 |

2.2 |

0.75 |

| Cr |

|

|

|

|

17 |

17 |

| Cr |

|

|

|

|

|

|

| Others |

|

|

Co50 |

|

1.4 Mn |

1.0 Mn |

| Fe |

Bal |

Bal |

Bal |

Bal |

Bal |

Bal |

* Heat treated

| Typical material composition and properties |

| Properties |

17-4PH* |

M2* |

Cu |

KOVAR |

Alloy-42 |

| g/cm3 |

7.6 |

>8.0 |

8.3 |

7.8 |

7.8 |

Tensile Strength

( MPa ) |

1200 |

1800 |

190 |

450 |

450 |

Elongation

( % ) |

4 |

0.5 |

25 |

25 |

25 |

| Hardness |

Max.HRc 38 |

Max.HRc 62 |

|

HRb 50 |

HRb 50 |

| C |

< 0.05 |

0.9 |

|

< 0.05 |

< 0.05 |

| Ni |

4 |

|

|

29 |

42 |

| Mo |

|

0.5 |

|

|

|

| Cr |

17 |

4 |

|

|

|

| Cr |

4 |

|

|

|

|

| Others |

|

2.0V |

|

Co17 |

|

| Fe |

Bal |

Bal |

Bal |

Bal |

Bal |

* Heat treated

| Dimemsional Tolerances for MIM |

| Dimemsion |

Standard Tolerance ( mm ) |

| 50.0 |

+/- 0.250 |

| 25.0 |

+/- 0.125 |

| 12.0 |

+/- 0.05 |

| 6.0 |

+/- 0.04 |

| 3.0 |

+/- 0.03 |

| 1.0 |

+/- 0.03 |

Sintering Alignment

【Back】 |

|

| |

| |

|

| |

© Copyright 2007 |

Taiwan

Sintered Metals Co., Ltd. |

|

| |

Taiwan Sintered

Metals Co., Ltd. |

(T):886-2-2268-2837 (F): 886-2-2269-4804 |

|

| |

All rights reserved. |

|

1Fl., No. 25-1, Tzyh Chyang St., TuCheng

Dist., |

| |

|

|

|

New Taipei City, Taiwan, R.O.C. |

|

| |

|

|

|

E-Mail:sales@tsm.com.tw |

|

|

| |

|

|

|

|

|

|

|

| |