|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

M I M |

|

|

|

|

|

| |

|

|

| |

The MIM process is the best way

to make small parts with a complex geometry. Beacuse of its high precision and the few

secondary opeations needed, MIM offers a cost competitive alternative to the traditional powder metallurty or investment casting process. |

|

| |

|

| |

|

| |

|

| |

|

|

|

|

| |

Field Application of MIM: |

|

|

|

| |

◆

Office Equipment |

|

|

|

| |

◆

Cable Communication/3C Accessory |

|

|

|

| |

◆

Vehicle/Motorcycle Engine Parts |

|

|

|

| |

◆

Aerospace Technology |

|

|

|

| |

◆

Watch case/band |

|

|

|

| |

◆

Hand/Pneumatic/Electric Tools |

|

|

|

| |

◆

Textile Industry |

|

|

|

| |

◆

Medical Instrument |

|

|

|

| |

◆

Lock |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Field Application Pictures of MIM: |

|

|

|

| |

|

|

|

|

| |

Computer

&

Notebook Parts |

|

| |

( LCD display bracket

& housing ) |

|

| |

|

|

| |

SS316L

&

17-4PH |

|

| |

|

|

| |

Instead of Al/Zn die casting |

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

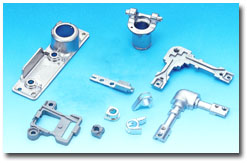

Lock Sets |

|

| |

|

|

| |

17-4PH or Fe-8%

Ni Cr Plated |

|

| |

|

|

| |

Instead of investment casting |

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Hand Tool Parts, Gear Stopper High Speed Steel M2, Low Alloy Steel

Switcher Cover |

|

| |

|

| |

|

| |

|

|

| |

Fe-8% Ni |

|

| |

|

|

|

| |

Instead of P/M

&

investment casting |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Pneumatic/Electric Power Tool Parts |

|

| |

|

|

| |

Fe-8%

Ni/M2/Alloy Steel |

|

| |

|

|

| |

Chuck Jaws, Vibrator Lever, Gear

Pin, |

|

| |

Gear Holder |

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Sewing Machine

Parts |

|

| |

|

|

|

| |

Thread Pick-up

Lever, |

|

| |

High Speed Steel M2 |

|

| |

|

|

|

| |

Instead of machining parts |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

SMT Insert

Machine Parts, |

|

| |

Pick

& Place Lever |

|

| |

|

|

| |

Fe-8%

Ni Cr Plated |

|

| |

|

|

| |

Instead of machined or cast parts |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Linear

Guideways, Slider Block, |

|

| |

Automation

&

Robot Parts |

|

| |

|

|

| |

M2 or 4605 Cr

Plated |

|

| |

|

|

| |

Instead of machining parts |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Hings used in 3C

industry |

|

| |

|

|

|

| |

(replace precision casting) |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

© Copyright 2007 |

Taiwan

Sintered Metals Co., Ltd. |

|

| |

Taiwan Sintered

Metals Co., Ltd. |

(T):886-2-2268-2837 (F): 886-2-2269-4804 |

|

| |

All rights reserved. |

|

1Fl., No. 25-1, Tzyh Chyang St., TuCheng

Dist., |

| |

|

|

|

New Taipei City, Taiwan, R.O.C. |

|

| |

|

|

|

E-Mail:sales@tsm.com.tw |

|

|

| |

|

|

|

|

|

|

|

|